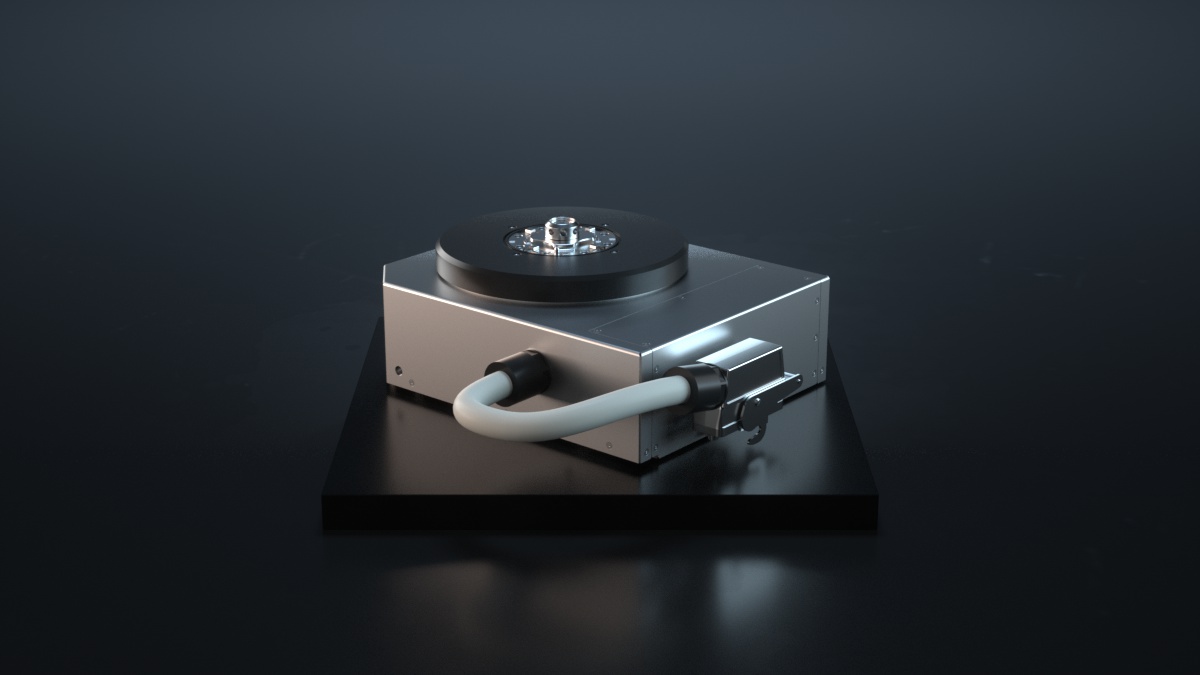

B-Axis | Integrated or Modular

The oil-hydrostatic B-Axis turns the IL-Series machine platforms into 4- or even 5-axes systems. It rotates

360° continuously to align diamond tools for tool-normal machining, to set certain required pre-angular

adjustments for metrology sensors, or it allows for raster grinding or milling curved surfaces. With a

standardized NanoGrip interface at the top of the rotary axis tool holders, a grinding or milling spindle as

well as metrology sensors can be mounted easily & efficiently.

The B-Axis is based on a wide span oil hydrostatic bearing design for advanced tilt stiffness. A direct torque

drive allows for rotations up to 30 rpm continuously. A specially designed break with ultra-low clamping

distortion can clamp the rotor to switch off the motor for pre-angular adjustments. A large diameter encoder

ring guarantees highest position precision and low positioning noise.

Due to the ultra-compact design of the axis, it can be integrated into IL300 series machines or alternatively,

it can be mounted as a modular unit on IL500 & IL600 series. For the modular unit, NanoGrip interfacing to the

machine axis slide allows for fastest axis integration and automated alignment. Oil, water and air supplies

are being connected automatically.