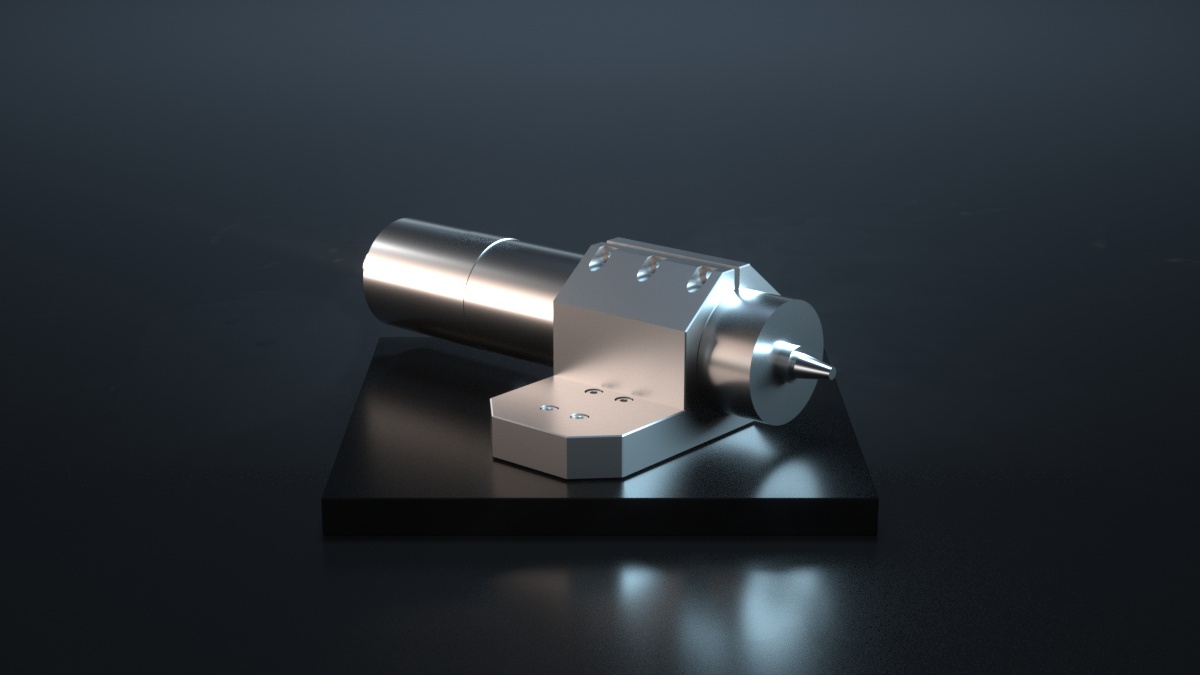

Grinding & milling spindle

General

Description

Type

Aerostatic ultra-precision spindle

Motor

Direct drive, 400 V, 0.33 Nm

Speed

60.000 rpm or 80.000 rpm

Tool interface

HSK25, spring-less

Cooling

Water

General

Description

Type

Aerostatic ultra-precision spindle

Motor

Direct drive, brushless

Speed

60.000 rpm

Tool interface

Collet

Cooling

Water

Accuracy

Shaft error motion < 25 nm