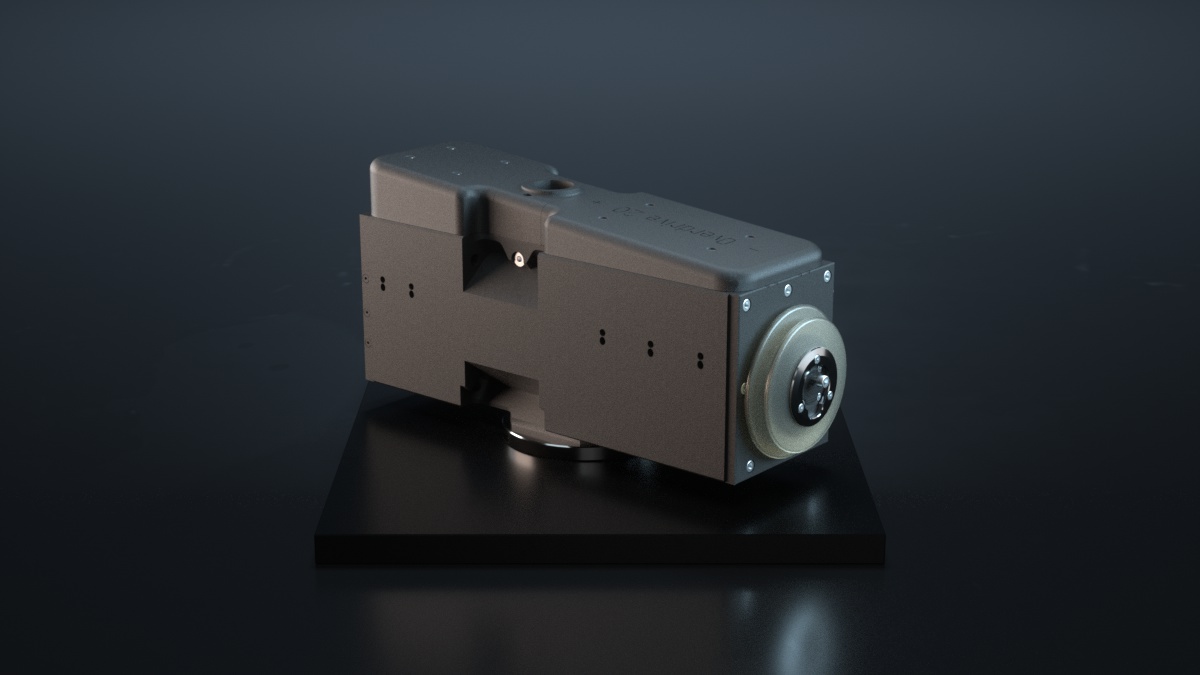

The Overdrive20 is a high dynamic short stroke air bearing axis for the efficient free form optics and

micro-structure generation. With a total stroke of 20 mm the Overdrive20 closes the gap between conventional

short stroke Fast Tool Servos and the Slow Tool Servo with insufficient dynamics.

The Overdrive20 is designed as a double slide air bearing axis with a highly efficient reaction force

compensation to avoid any parasitic dynamic excitation in the ultra-precision machine tool. Only one slide

positions the diamond tool for cutting, the second slide with an identical mass to the first slide accelerates

in the opposite direction to generate a counter force. Following errors of the carrier axis for the

Overdrive20 can be kept down below 5 nm at Overdrive20 operation.

With the DirectDrive3D control system architecture, the Overdrive20 operates at fixed 10.000 set points per

second and full up-front interpolation among all machine axes.

There are no angular offsets or interpolation delays as know from Master-Slave Fast Tool Servos with this

set-up. Using the ILAnalyze software package allows for upfront dynamic following error analysis in a 3D plot

to optimize process parameters for best part quality.

With the NanoGrip interface the Overdrive20 can be mounted inside the ultra-precision

machine within minutes

at perfect alignment. The Overdrive20 uniquely combines ultimate precision with highest productivity.