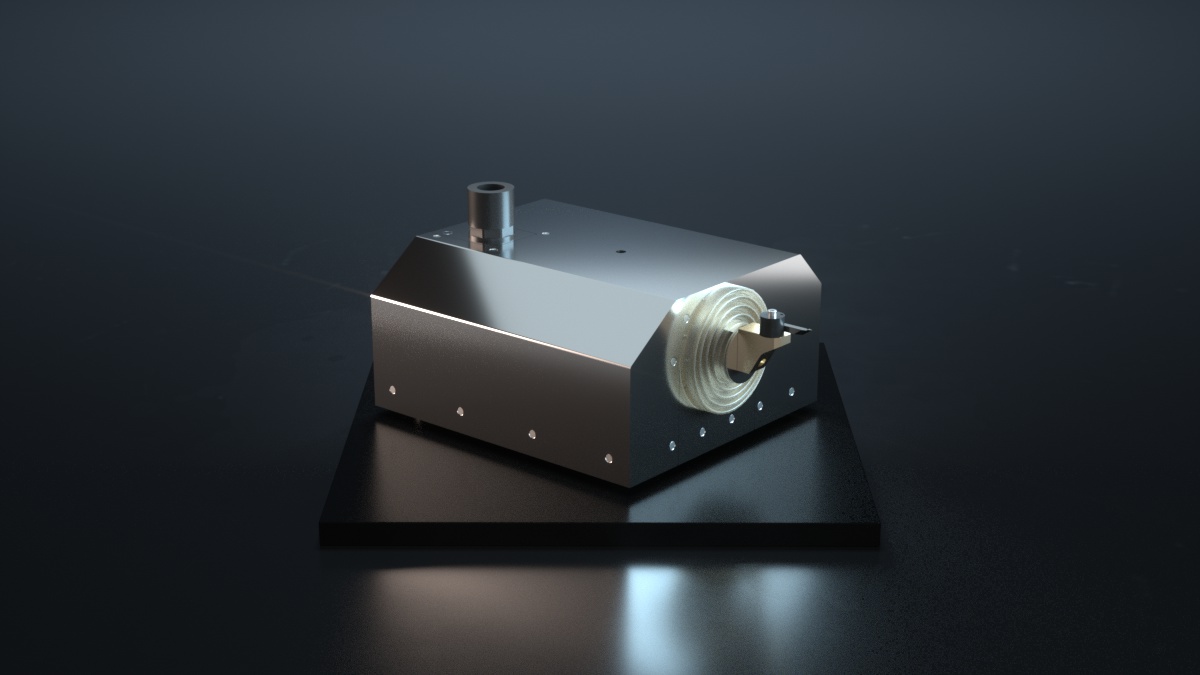

The Overdrive50 is a high dynamic medium stroke oil hydrostatic linear axis for the efficient free-form optics

and micro-structure generation. With a total stroke of 50 mm the Overdrive50 closes the gap between

conventional short stroke Fast Tool Servos and the Slow Tool Servo with insufficient dynamics. Head up

displays, space mirrors and other large stroke non-rotationally symmetric optics can be produced to highest

quality standards at best efficiency.

The Overdrive50 has a light-weight slide with only 3kg of moving mass compared to a slow slide system with

> 100kg. As only 1/40th of the weight needs to be accelerated, dynamics can be significantly increased to

shorten cycle times. Reaction forces disturbing the machine structure are being reduced accordingly. The oil

hydrostatic bearing system provides optimized damping for the slide as a cantilever in the extreme positions.

An iron-less linear drive allows for sub-nanometer following errors of the light weight axis.

With the DirectDrive3D control system architecture, the Overdrive50 operates at fixed 10.000 set points per

second and full up-front interpolation among all machine axes. There are no angular offsets or interpolation

delays as know from Master-Slave Fast Tool Servos with this set-up. Using the ILAnalyze software package

allows for upfront dynamic following error analysis in a 3D plot to optimize process parameters for best part

quality.

With the NanoGrip interface the Overdrive50 can be mounted inside the ultra-precision

machine within minutes at perfect alignment. The required oil, water and air supply is integrated in the base

platform, automatically connecting. The Overdrive50 uniquely combines ultimate precision with highest

productivity.