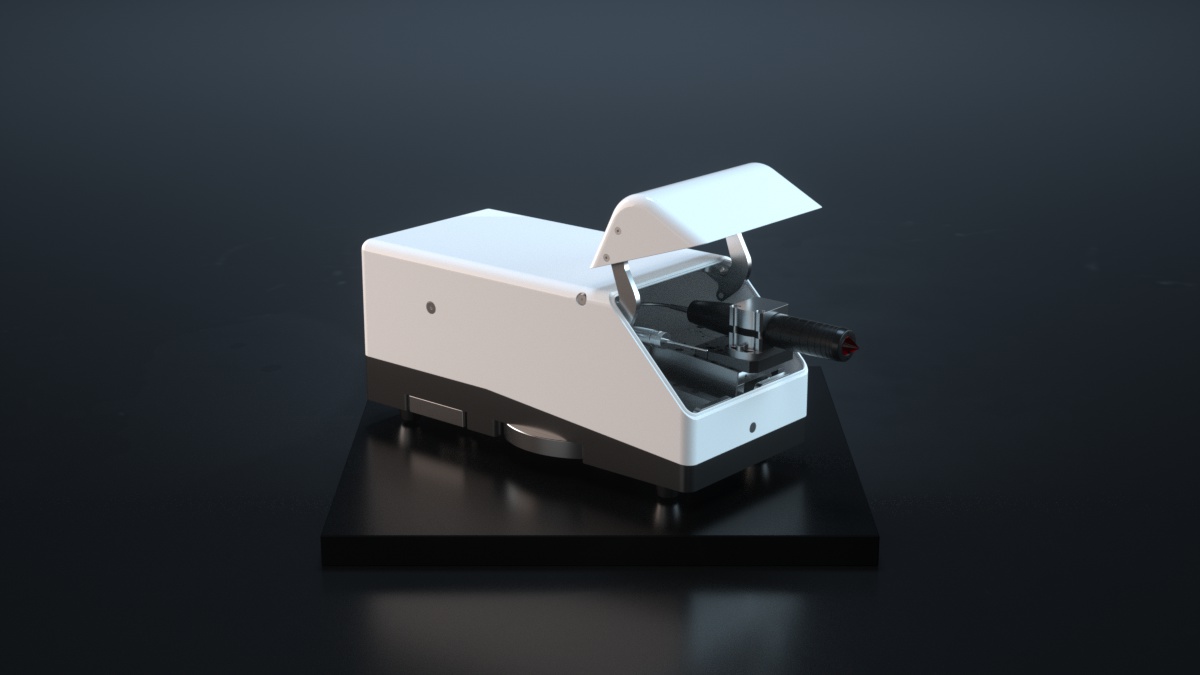

Sensor Module | Double

The sensor module allows for two sensors to be used in a fully automated way simultaneously. Two linear air

bearing axes position the sensors into the measurement range or retract into the garage. A classical sensor

combination especially for alignment turning is the chromatic confocal together with the 3DOF tactile sensor.

Alternative sensors can be installed and aligned. A control system integrated hood protects the sensors and

axes during machining and opens up for measurement only. The mechanical and electrical integration of the unit

is identical to the Sensor Module | Single.

Sensor Module | Single

The module allows for a fully automated sensor integration into IL series ultra-precision machine tools. An

ultra-precise linear air bearing axis drives the sensor into the measurement range or into the protective

position inside the garage. A control system integrated hood protects the sensor during machining and opens up

for measurement only. The module holds for the chromatic confocal, the tactile or the LVDT probe

alternatively. With a NanoGrip interface, the unit can be installed inside the machine within minutes at

highest geometrical repeatability. Electrical and signal connectivity is integrated into the machine slide for

best protection and compact set-up.

Sensor Module | Basic

The module holds and vertically positions a single sensor without automation. A protective cover can be

positioned to secure the sensor during machining but still to leave it perfectly aligned inside the machining

room. As standard configuration, the module comes with the chromatic confocal sensor for non-contact surface

scanning. Alternatively, a 3DOF tactile sensor or an inductive LVDT can be mounted to the platform. A

microscope camera for edge detection or dimensional metrology can be mounted. With a NanoGrip interface, the

unit can be installed inside the machine within minutes at highest geometrical repeatability.