ILCENTRIC Package

The ILCENTRIC package will extend the functionality of an IL300 or IL500 series machine to a alignment turning platform. Up to three different cooperating sensors allow for measuring spherical, aspherical or even free form optics to automatically center turn them to single digit seconds angular alignment. The Innolite approach without mechanical alignment chuck uniquely combines the benefits and the usability of a diamond turning lathe with those of a fully automated high performance alignment turning machine at the same time. The highest level of automation, a rigid set-up for cutting hard to machine materials such as stainless or titanium and a horizontal lens alignment for optimized ship removal are just a few of the key benefits over conventional tools with a mechanical alignment chuck.

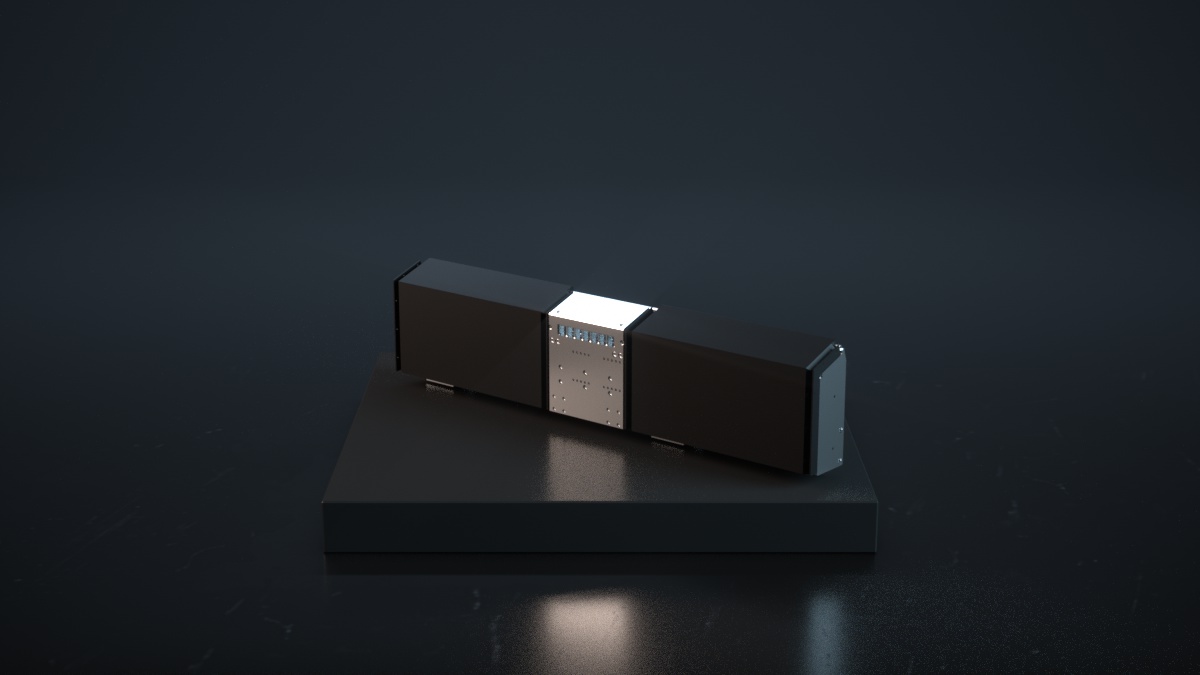

W-Axis

The W-Axis is an add on linear axis to position an autocollimator or Laser Alignment Sensor LAS to characterize the optical axis of a spherical lens. With a linear direct drive, a high precision optical encoder and high precision mechanical guideways, the sensor can be positioned with sub-micron accuracy. The included and fully automated garage allows for sensor protection during machining.

ILCENTRIC Set | Autocollimator

ILCENTRIC Set | Laser Alignment