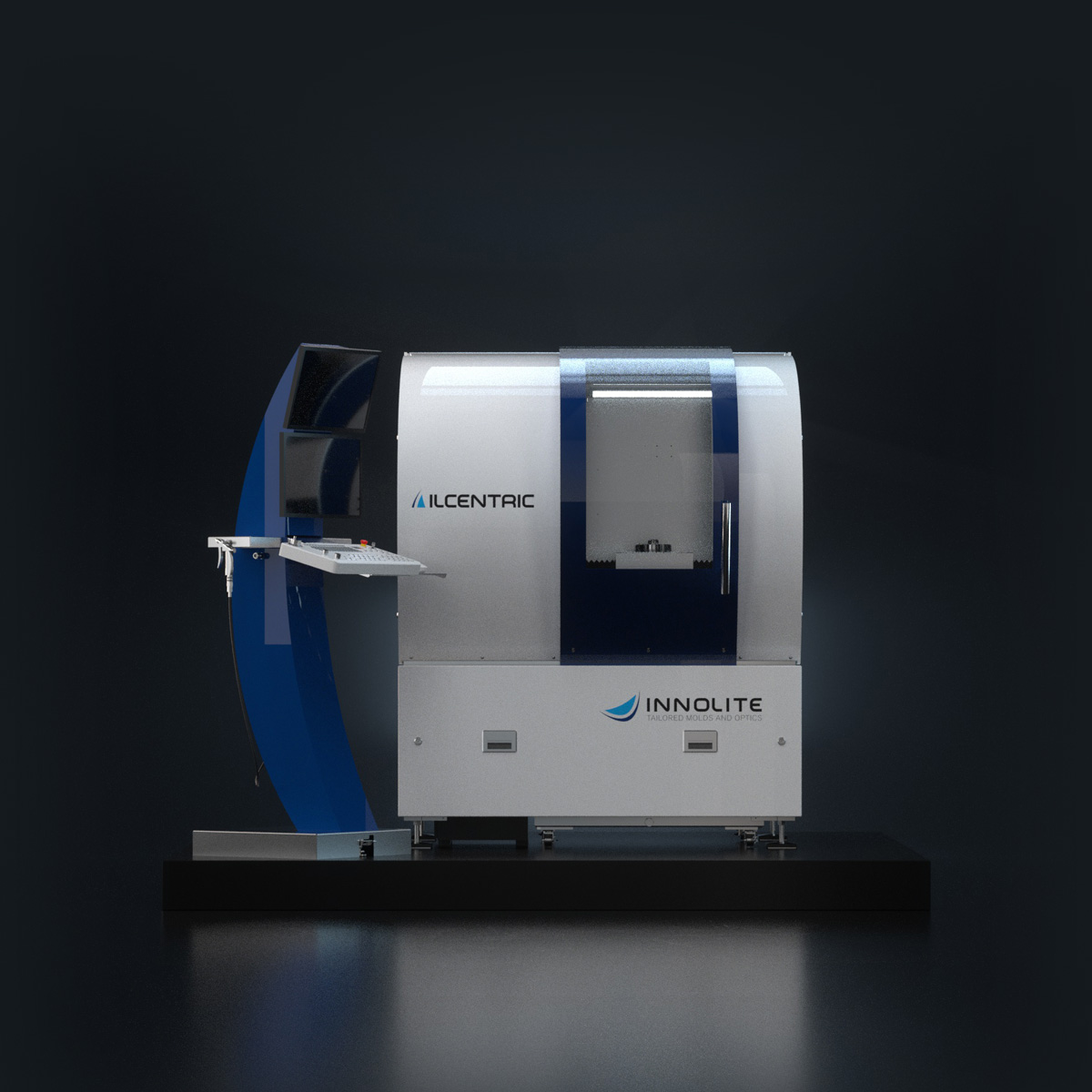

ILCentric300

UP Lathe

optics centering. optics turning. precision mechanics turning.

The ILCentric300 is the leading ultra-precision machine platform for high-performance centering of mounted lenses with diameters of up to 250 mm. Various integrated optical and tactile sensors enable the centering of all relevant modern optics. The ILCentric does not use a conventional center chuck, but a unique dynamic turning process to correct the alignment of the optical axes from lens to frame. As a result, the machine can be used not only for centering turning, but also for the diamond turning process and the high-precision manufacturing of mechanical components. The machine utilization can thus be individually adjusted between centering turning and ultra-precise manufacturing in order to minimize depreciation periods.

Dive into the details:

ILCentric300 General

Linear Axis

Workholding Spindle

METROLOGY

Videos

Innolite platforms are designed to be modular

The work spectrum of the ILCentric300 can be expanded with a large number of different modules. The following is a list of all modules, arranged according to their area of application