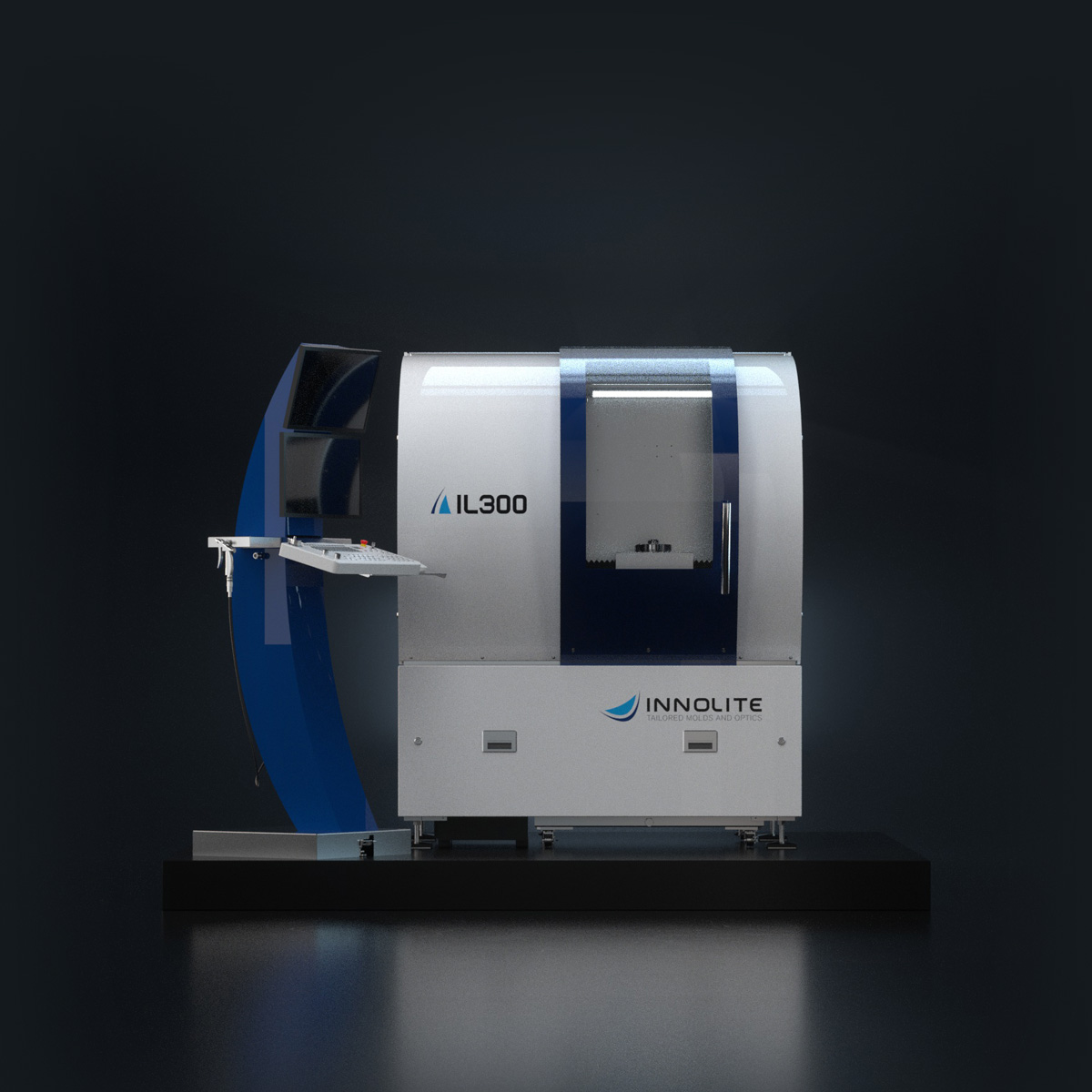

IL300

UP Lathe

flexible. productive. allrounder.

The IL300 is the leading ultra-precision diamond lathe for highly productive, highly

flexible optics manufacturing. It was developed to increase productivity in ultra-precision technology.

Consistently integrated zero-point clamping systems with submicron accuracy, a stainless-steel housing and a

highly dynamic lightweight construction for maximum dynamics. The applications range from standard diamond

turning to free-form manufacturing and microstructure generation to diamond turning of steel and infrared

materials with ultrasound support (ILSONIC).

Also look at

Key Features

NanoGrip

Our NanoGrip zero-point clamping system interface allows for submicron repeatability in exchanging tools,

sensors for in line metrology and work pieces with only a few seconds. It’s a fundamental feature for the

leading-edge productivity of Innolite´s ultra-precision machines.

Individual pallets with four index positions for rotating at 90° angular steps are the exchangeable

interface for the chucks mounted and aligned at the spindle (for work piece exchange) and at the Z-slide

(for tool and sensor exchange).

Due to it´s robust design, turning operation of up to 5.000 rpm is supported on the spindle side. With a

vacuum chuck adapter provided by Innolite, standard diamond turning functionality meets high productivity in

next generation optical manufacturing.

Dive into the details:

IL300 General

Linear Axis

Workholding Spindle

Videos

Innolite platforms are designed to be modular

The work spectrum of the IL300 can be expanded with a large number of different modules. The following is a list of all modules, arranged according to their area of application