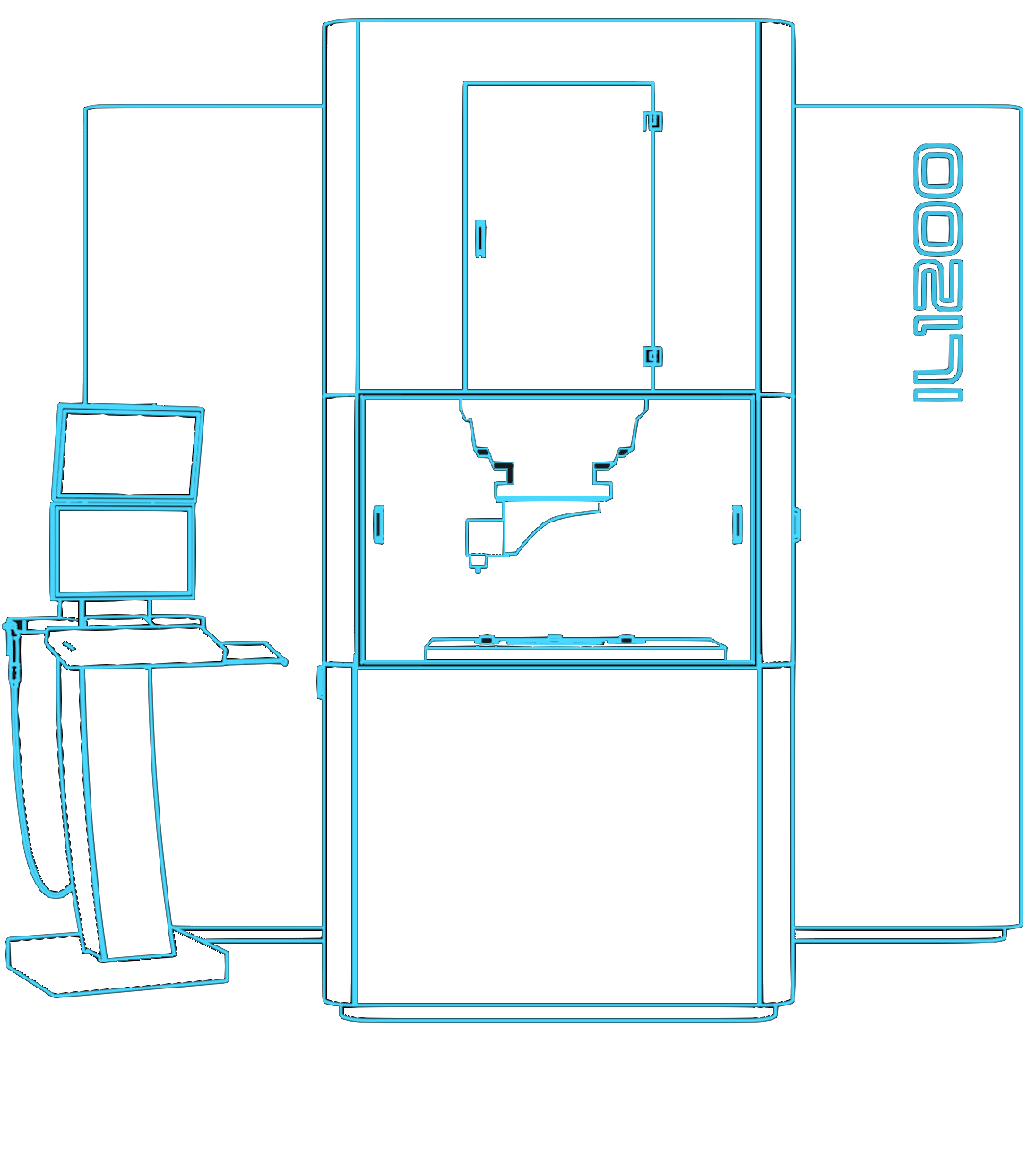

IL1200

IL1200 is an ultra precision 4-axis CNC large vertical machining center (large diameter diamond lathe), which consists of machine base (natural granite integral body structure), self leveling pneumatic vibration isolation system, Beckhoff CNC industrial standard high-performance controller PC, digital servo drive system, a cutting fluid spray cooling system, water circulation cooling system for all linear axis and spindle, air temperature control and filtering system, non-contact online measurement, programming software, Nanogrip Zero-point clamping, optical tool setting, spindle balance module, etc; It is a large turning platform to machine large scale optical mirrors of diameters up to 1.2 m and the max height of part up to 350 mm. The machining accuracy is less than 23 nm RMS within 300 mm diameter area.

It can process components such as large aperture flat surfaces, spherical surfaces, aspherical surfaces and other rotationally symmetric surface,non-symmetric freeform surfaces such as off axis paraboloids, polynomial freeform surface and so on. It can also process infrared sub wavelength micro nanostructures on large aperture aspherical substrates.

The material which could be cut includes Aluminum, brass, Nip and other non-ferrous metal. Germanium, silicon and other crystal materals, PMMA and other Polymer materials.

The hydrostatic supported gantry structure can achieve higher accuracy in diamond turning. The vertical arrangement of the main spindle can optimize the installation and precise alignment of the mirror structure under stress, without being affected by gravity. The NanoGrip interface on the Z-axis sliding end ensures that different tool handles, other fixtures, or measuring sensors are adapted to the complex machining sequence that follows. High precision diamond turning can be achieved through ILCAM software, including programming functions for rotational symmetric surfaces such as plano, spherical, aspheric surfaces and other rotationally symmetric surface, off axis parabolic surfaces, and non-symmetrical free form surfaces, as well as 2D and 3D compensation machining and microstructure surface machining processes.

Key Features

NanoGrip

Our NanoGrip zero-point clamping system interface allows for submicron repeatability in exchanging tools, sensors for in line metrologoy and work pieces with only a few seconds. It’s a fundamental feature for the leading-edge productivitys of Innolite’s ultra-precision machines.

Individual pallets with four index positions for rotating at 90° angular steps are the exchangeable interface for the chucks mounted and aligned at the spindle (for work piece exchange) and at the Z-slide (for tool and sensor exchange).

Due to it’s robust design, turning operation of up to 5000 rpm is supported on the spindle side. With a vacuum chuck adapter provided by Innolite, standard diamong turning funcionality meets high productivity in next generation optical manufacturing. The repeatability of the system is less than 0.5 um.

Dive into the details:

IL1200 General

Linear Axis

Workholding Spindle

Accessories

Filter grade:G4, E11, E12, H13, etc.

Video