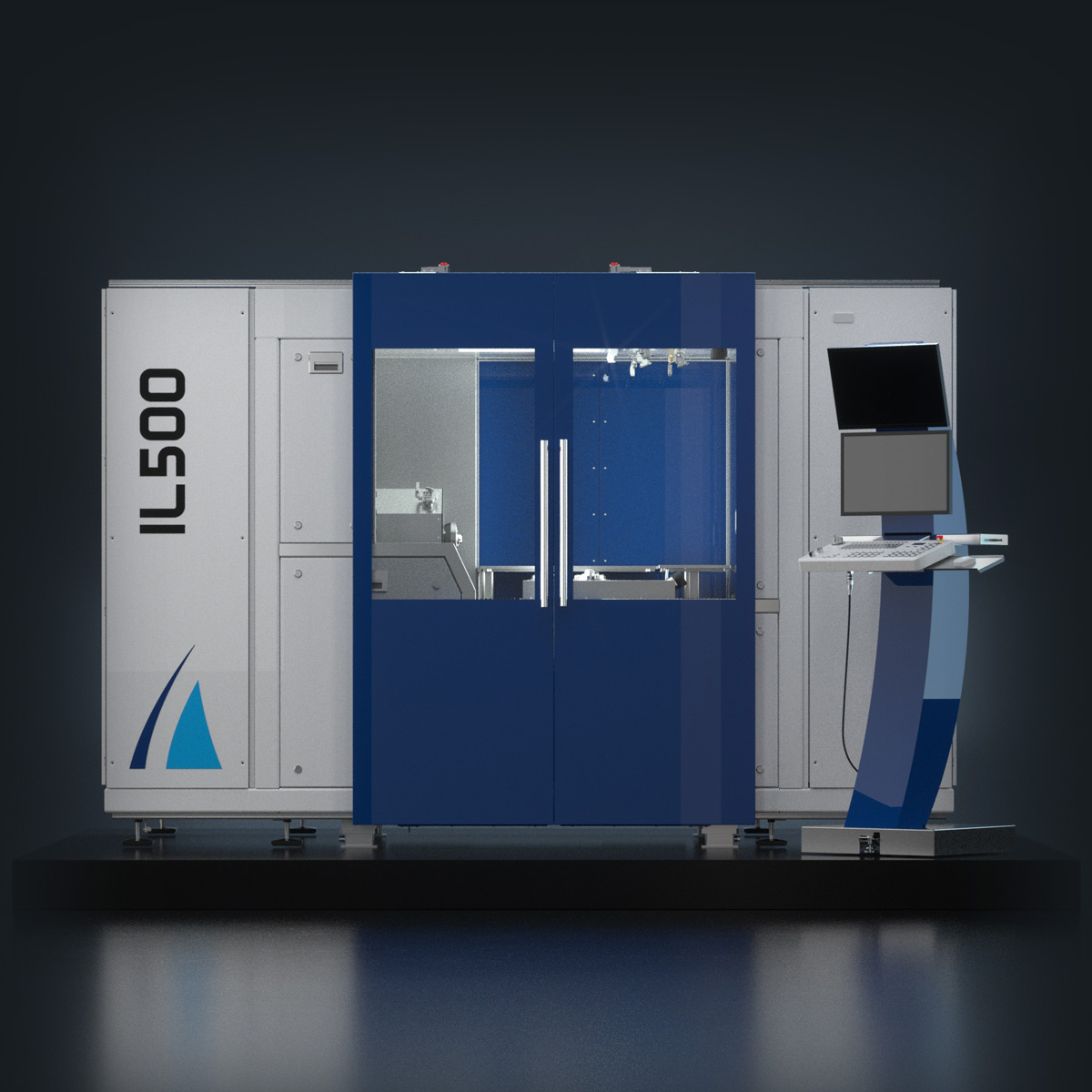

IL500

UP Lathe

large scale. process combination. automation.

In addition to large components with diameters of up to 500 mm, the IL500 offers unique options for simultaneous process equipment or parallelization of processes. With three or four ultra-precision axes, spherical, free-form and also micro-structured optics can be efficiently manufactured. Integrated measurement technology enables the inline characterization of surfaces with direct compensation. In this way, preprocessing steps and ultra-precise finishing can be efficiently combined with the highest levels of accuracy. Prepared for loading with robots, the machine is the ideal platform for automated series production.

Dive into the details:

IL500 General

Linear Axis

Workholding Spindle

Innolite platforms are designed to be modular

The work spectrum of the IL500 can be expanded with a large number of different modules. The following is a list of all modules, arranged according to their area of application